US Aggregates Receives Positive Feedback from Annual Refresher Training

Friday, January 26th, 2024

US Aggregates has completed their annual refresher training, a requirement placed by the Mine Safety and Health Administration (MSHA) to ensure miners are up to date with the latest safety standards and best practices. With 17 active locations around Indiana, the trainings were held in three locations to ease the commute of employees: Fair Oaks in the Northwest, Portland in the East and centrally located Indianapolis. Each employee is only required to attend one training session.

While holding annual refresher training is an MSHA requirement, US Aggregates uses it as an opportunity to bring locations together and share ideas.

“It’s a way for us to get multiple mines grouped together to share ideas, stories and learn from each other,” Safety Manager Eric Reno said. “We use annual refresher to get lots of information out to the miners and discuss trends that are occurring in our industry.”

For US Aggregates, annual refresher trainings are an ever-evolving process where new ideas are created and implemented based on the feedback we receive from our miners. Developing new activities and presentations helps keep the training fresh and increases engagement and retention.

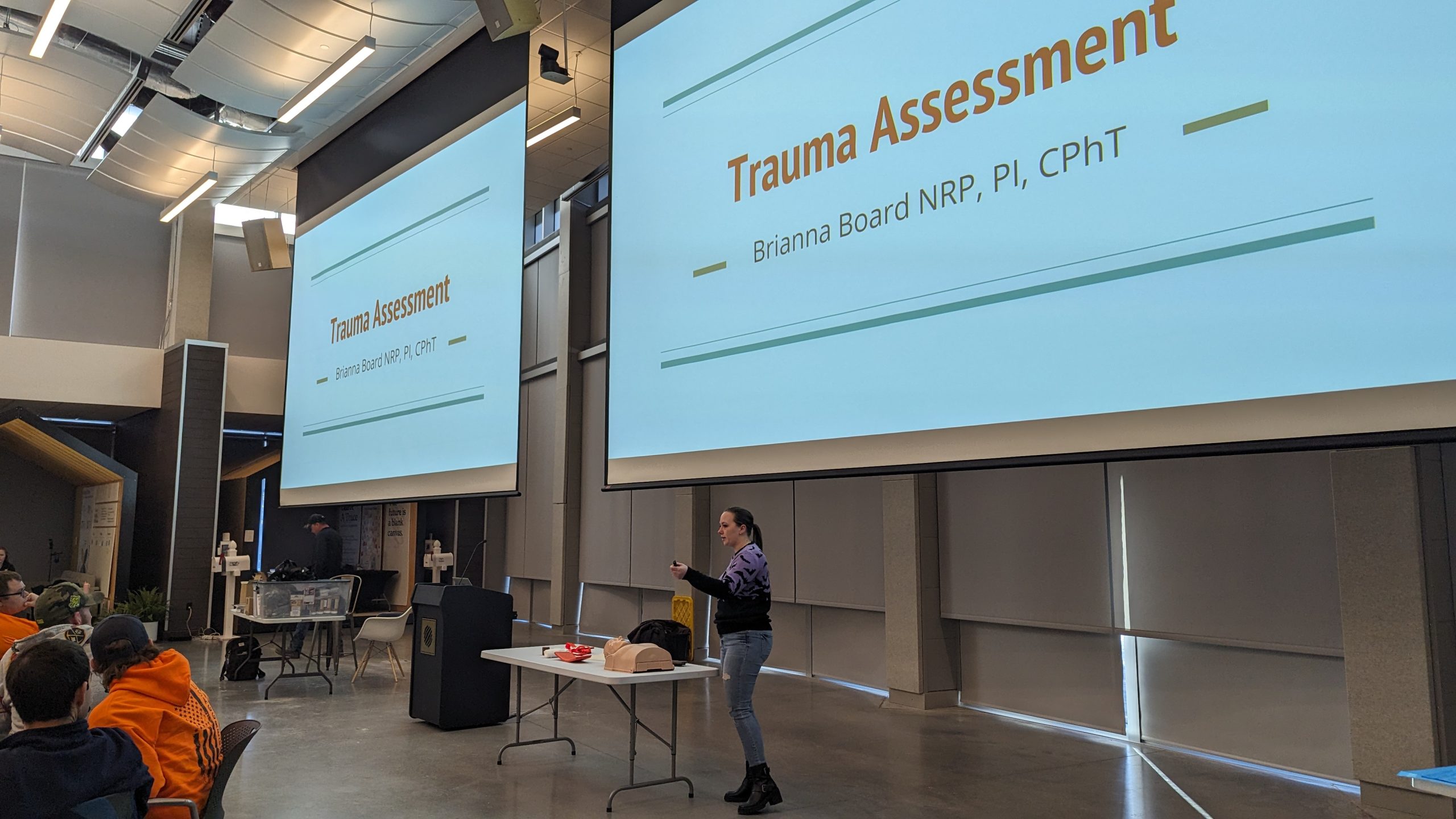

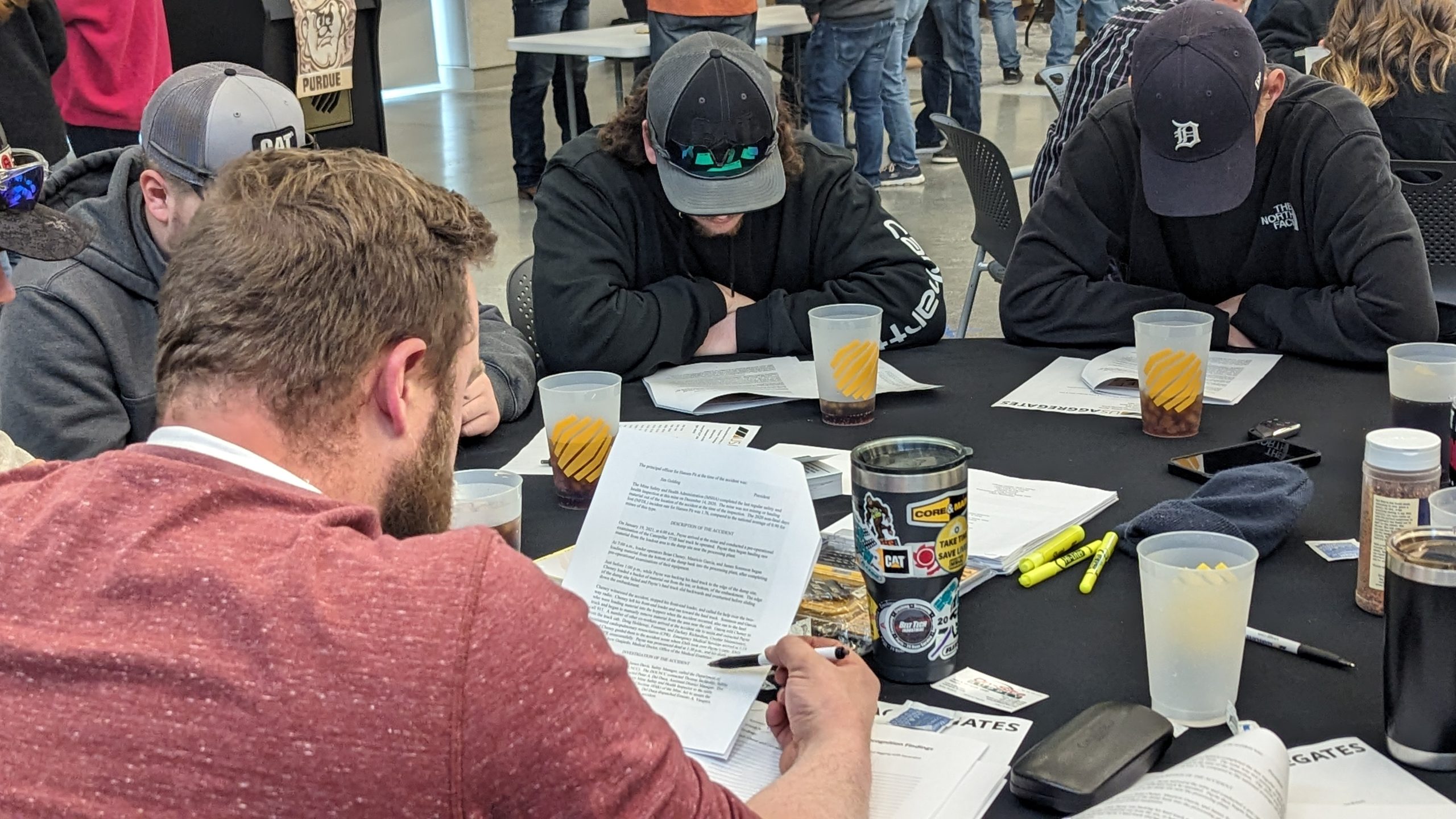

This year’s training sessions included an interactive first aid station where employees were taught how to properly apply a tourniquet, dress open wounds and create a splint from everyday objects that could be found at a mine site. Employees also watched simulated training videos to try to catch potential safety hazards or violations* and find the violation in the MSHA handbook (*all training videos were simulated and at no point was anyone subject to any danger or violations). Vendors joined to demonstrate proper techniques for safety equipment such as harnesses and tools. The safety and environmental team also shared a recap of some emergency action drills from the previous year and reviewed what went well and what could have been done better. Read more about our 2023 Emergency Action Drill recap here.

In addition to the training received, a boot truck was brought to each training location and employees were given a new pair of steel-toe safety boots.

After each day of training, US Aggregates collected feedback from participants to better serve our team.

“We have received an overwhelming amount of positive feedback,” Eric said. “The responses we got from all the trainings has been great, so we are going to continue moving in the direction that we are with the trainings.”

US Aggregates President John Schmidt sees annual refresher training continuing to improve each year.

“I am proud of the work and coordination that went into this year’s annual refresher training and feel that it was our best session yet,” John said. “The hands-on training was extremely positive as it allowed everyone to move around and create opportunities for shared conversations around real life events.”