US Aggregates Emergency Action Drills: Year in Review

Thursday, December 14th, 2023

Throughout the year, US Aggregates prepared site specific Emergency Action Drills to help prepare our team members when emergencies arise. These drills simulate real events that could occur and allow our plants the opportunity to learn and ask questions regarding safety procedures and protocols. Our sites partnered with local emergency personnel to receive training and feedback as well as reinforce action plans for when real emergencies arise. Safety and Health Rep Shalya Meinders sees EADs as an integral part of the US Agg safety culture. “By doing these drills, it refreshes our employees on their sites emergency procedures and puts them to the test,” Shayla said. “We do our best to minimize the hazards on mine sites, but we want to be prepared for anything that could happen.”

Disclaimer: All EAD’s were performed with safety in mind. The following situations are educational simulations. At no point were crew members exposed to harm. Fake blood was used to simulate injuries.

Delphi, IN

Led by Plant Manager Putter Hahn, Delphi’s EAD simulated a drilling crew member being suspended over the high wall. To prepare for the drill, a safety dummy was placed in a harness and lowered off the high wall.

When the drill began, Putter observed the response time of the crew to test their visual awareness. Once the dummy was discovered, the emergency was communicated over the radios and the plant went into action. The simulation allowed the team the opportunity to revisit emergency procedures and emphasize what roles each member plays in these kinds of situations.

Key Takeaways: This drill highlighted the opportunity of upgrading the site’s radio system and drilling tie off points. The team is looking into adding trauma bags and harnesses to more of the trucks as well as researching visual aids for drillers that will help alert other crew members in emergency situations.

Columbus, IN

Led by Plant Manager Putter Hahn, Delphi’s EAD simulated a drilling crew member being suspended over the high wall. To prepare for the drill, a safety dummy was placed in a harness and lowered off the high wall.

When the drill began, Putter observed the response time of the crew to test their visual awareness. Once the dummy was discovered, the emergency was communicated over the radios and the plant went into action. The simulation allowed the team the opportunity to revisit emergency procedures and emphasize what roles each member plays in these kinds of situations.

Key Takeaways: This drill highlighted the opportunity of upgrading the site’s radio system and drilling tie off points. The team is looking into adding trauma bags and harnesses to more of the trucks as well as researching visual aids for drillers that will help alert other crew members in emergency situations.

Ridgeville, IN

Led by Plant Manager Putter Hahn, Delphi’s EAD simulated a drilling crew member being suspended over the high wall. To prepare for the drill, a safety dummy was placed in a harness and lowered off the high wall.

When the drill began, Putter observed the response time of the crew to test their visual awareness. Once the dummy was discovered, the emergency was communicated over the radios and the plant went into action. The simulation allowed the team the opportunity to revisit emergency procedures and emphasize what roles each member plays in these kinds of situations.

Key Takeaways: This drill highlighted the opportunity of upgrading the site’s radio system and drilling tie off points. The team is looking into adding trauma bags and harnesses to more of the trucks as well as researching visual aids for drillers that will help alert other crew members in emergency situations.

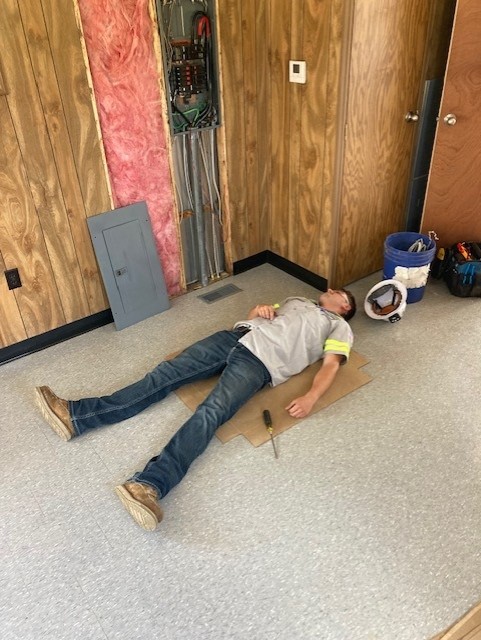

Crawfordsville, IN

In reference to their new scale house being built, Crawfordsville’s EAD simulated a drill where an onsite contractor was found unresponsive after a possible electrocution. The drill was performed when both the plant manager and leadman were offsite, requiring the team to change their normal order of communication.

Key Takeaways: After the drill, the crew reflected on their communication paths and who should respond to the scene for assistance. The team was also reminded to be aware of their surroundings before coming into contact with the victim to prevent harm to themselves or others. The plant is also scheduled to receive AED training.

Springville, IN

Going along with September’s safety topic of the month, Springville crew members simulated a first aid scenario where a crew member received head trauma. The drill simulated a service truck being struck with a loader bucket, injuring both team members inside. For safety purposes, the truck was secured prior to the EAD.

During the drill, retired EMS professionals observed the team’s response and scored them on their performance. The crew was then trained in properly applying a tourniquet and neck brace as well as treating shock. They learned how to stabilize a victim with a neck injury and how to properly transport someone on to a backboard.

Key Takeaways: The crew was reminded to be aware of their surroundings and identify any potential hazards before offering help. The drill helped reinforce decision making skills and strengthen the team’s communication.

243/Deer Creek

Lead by Equipment Operator and Loader, David Lovejoy, Deer Creek simulated a man down scenario where a crew member was found unresponsive in a manlift. Once the drill was announced, team members worked to bring the victim down while they waited for first responders. To assist with the drill, Putnam County EMS and the Cloverdale Volunteer Fire Department responded to the scene.

After the drill was complete, EMS had the opportunity to take a tour of the plant to help them better understand the site and plan routes in case of a real emergency. The crew participated in manlift training and discussed the findings from their drill.

Key Takeaways: The crew was able to communicate action plans with local first responders and reinforce emergency plans to new employees. Additionally, the team was re-trained on manlift operation.

Thorntown, IN

For their EAD, Thorntown simulated a vehicle collision that left a crew member injured and trapped inside. With the assistance from local volunteer fire fighters, the crew was able to observe and help with their rescue efforts.

Key Takeaways: The team was able to reinforce the importance of using a vehicles flashers, horns, and strobe lights. The drill served as a reminder to always be aware of your surroundings and keep yourself safe while helping others.

Linn Grove/Pleasant Mills, IN

For Linn Grove and Pleasant Mill’s EAD, the team simulated an unresponsive crew member on a manlift. The goal of the simulation was to observe if crew members were able to recognize potential hazards before helping. Additionally, emergency radio communications and procedures were practiced during the drill.

Key Takeaways: After the drill was complete, the team reflected on what hazards they were able to identify in the drill and what hazards they would have overlooked if this were a real emergency. This reinforced the importance of being aware of your surroundings at all times. The team also received updated task training on the manlift and air brakes. Updates are being made to the emergency contact information, site maps, and PPE stations.

Flat Rock, IN

For Flat Rock’s EAD, the team simulated an unresponsive crew member with a supposed head injury. The drill began when a crew member left to perform a routine inspection without notifying their team members. The goal of the drill was to test the team’s response time and see how long they would notice their team member is missing. The drill was performed when Flat Rock’s plant manager was offsite, causing communication to change.

Key Takeaways: Emergency contact lists were placed in key locations for when plant managers and other key leaders are offsite. The drill emphasized the importance of effective communication and working in pairs, when possible, to help alert others in emergency situations.

At US Aggregates, safety is at the forefront of all that we do. We would like to thank all local first responders for taking the time to assist with these drills. The educational experience has left our team members better prepared in emergency situations, which has the potential to save lives. If you would like to read about last year’s drills, visit our news page.